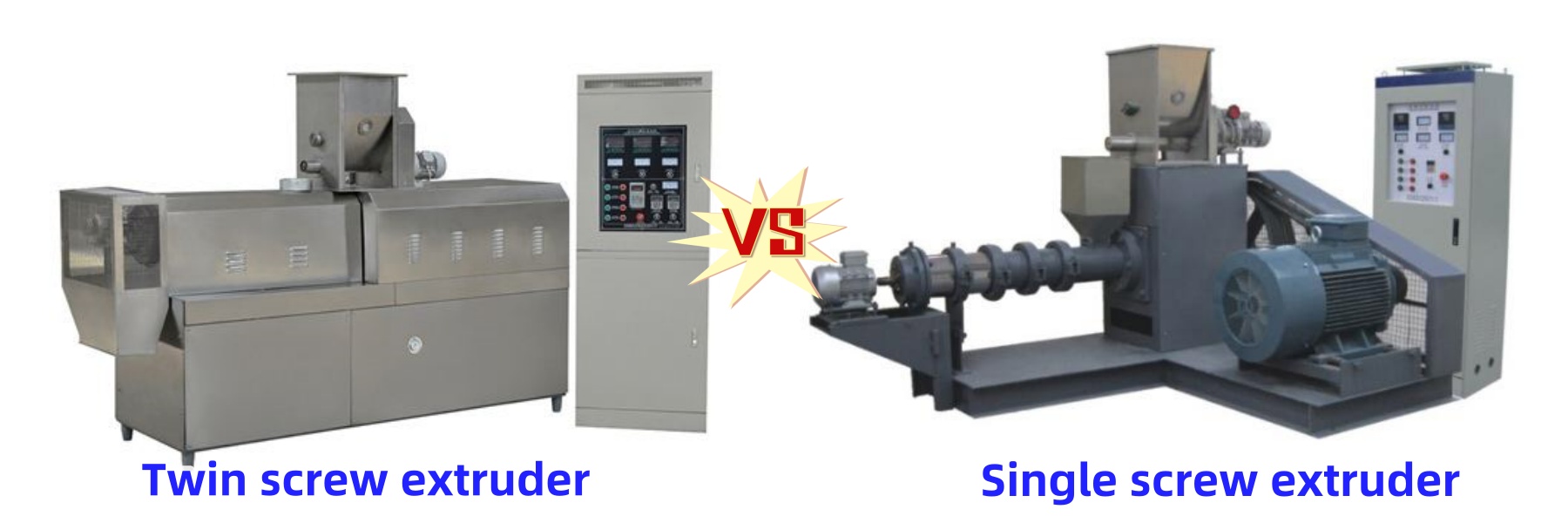

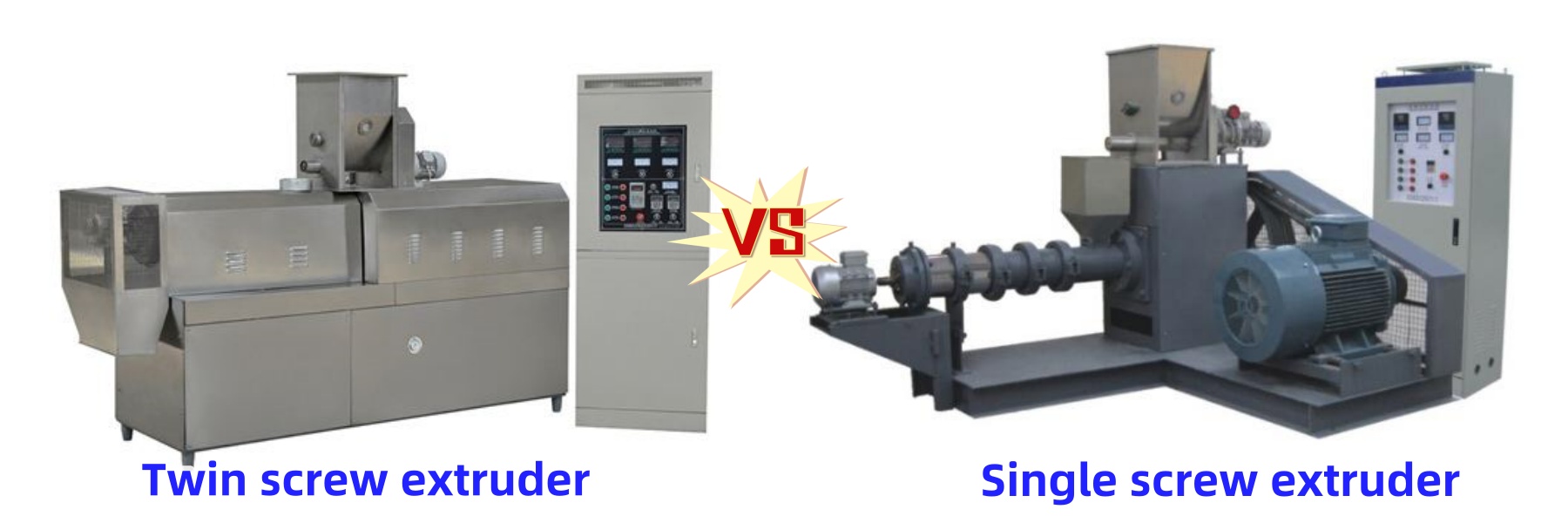

So far, more and more feed processing companies have gradually replaced traditional pellet mills with extruders to produce aquatic feed and other special feeds. However, many people still hesitate to choose a single-screw extruder or a twin-screw extruder when choosing an extruder. Below we will briefly analyze the cost, quality of the final product, and operation. I hope it will be helpful to you.

First: Cost

First: Cost

The price of a single-screw extruder is relatively low, but due to its simple structure and low technical and manufacturing levels, it can only be used to produce lower-grade feed in aquatic feed processing. Secondly, it wears quickly, and accessories need to be replaced frequently, resulting in high operating costs. It is usually a misconception that a single screw has less wear. In fact, during the twin-screw extrusion process, due to the stable material transportation and material flow characteristics, the wear of the material on the screw and the barrel sleeve is less than that of a single screw. Although there is one more screw, the cost of its accessories is still lower than that of a single screw.

Second: Final product quality

Single screw:

1. Poor product maturity, poor formability, uneven particles, and low finished product qualification rate.

2. Mainly used for low-end fish feed, chicken feed, horse feed, etc.

Twin screw:

1. The product has good maturity, uniform maturity, and rich taste. The particle size is uniform and the appearance is good. The finished product qualification rate is high and there is no waste.

2. Good puffing and strong floating.

3. Especially for feed below 2mm (high quality requirements), the differentiation is particularly obvious.

Mainly used to produce high-end fish food, dog food, and cat food. High added value and good profitability.

Third: Operation

Single screw:

1. Single screw extruder has poor stability.

2. Single screw is prone to overflow and back-spray in the feeding area, resulting in unstable material flow and blocking the machine, which is easy to cause machine failure and has high technical requirements for operators.

3. The screw is troublesome to clean. After each shutdown, the screw needs to be cooled and pulled out for cleaning, which is time-consuming and laborious.

4. The output fluctuates greatly.

Twin screw:

1. Twin screw is stable and efficient. Now the front end of the industry has developed three-screw equipment.

2. The twin screws are meshed with each other, and the equipment has an automatic cleaning function. There is no need to pull out the screw for cleaning. The equipment runs smoothly, the material does not flow back, it is not easy to crash, and the production capacity is stable.

3. Simple operation, automatic control, low requirements for operators.

When we choose extrusion equipment, we should not only consider the higher price of twin-screw extruders than single-screw extruders, but also consider the comprehensive cost performance and product production cost. Тwin screw extruder can not only meet the needs of aquatic feed in the breeding industry, but also achieve a high cost performance. It is a good choice for the current feed processing industry.