1.Principle of vacuum freeze drying

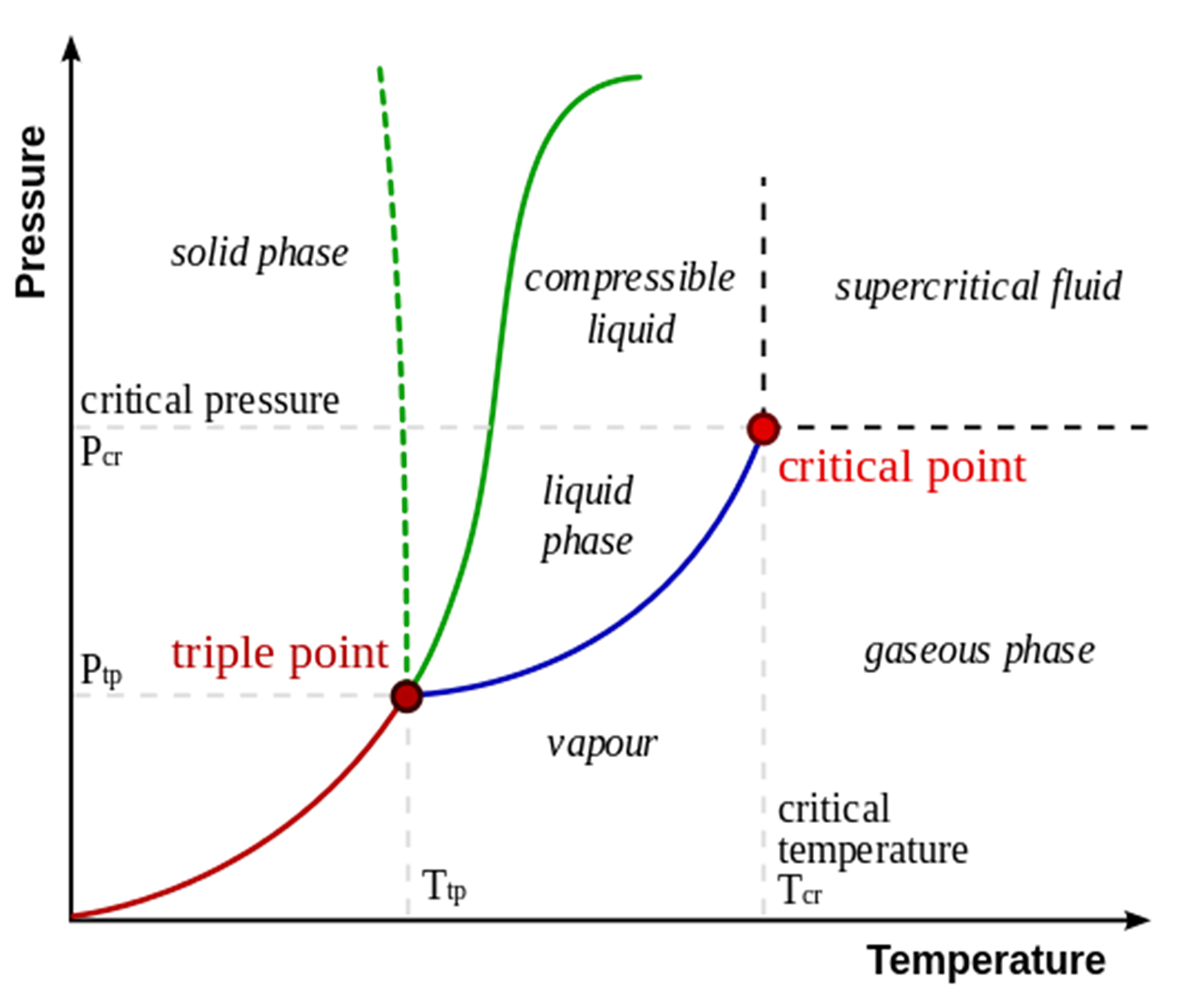

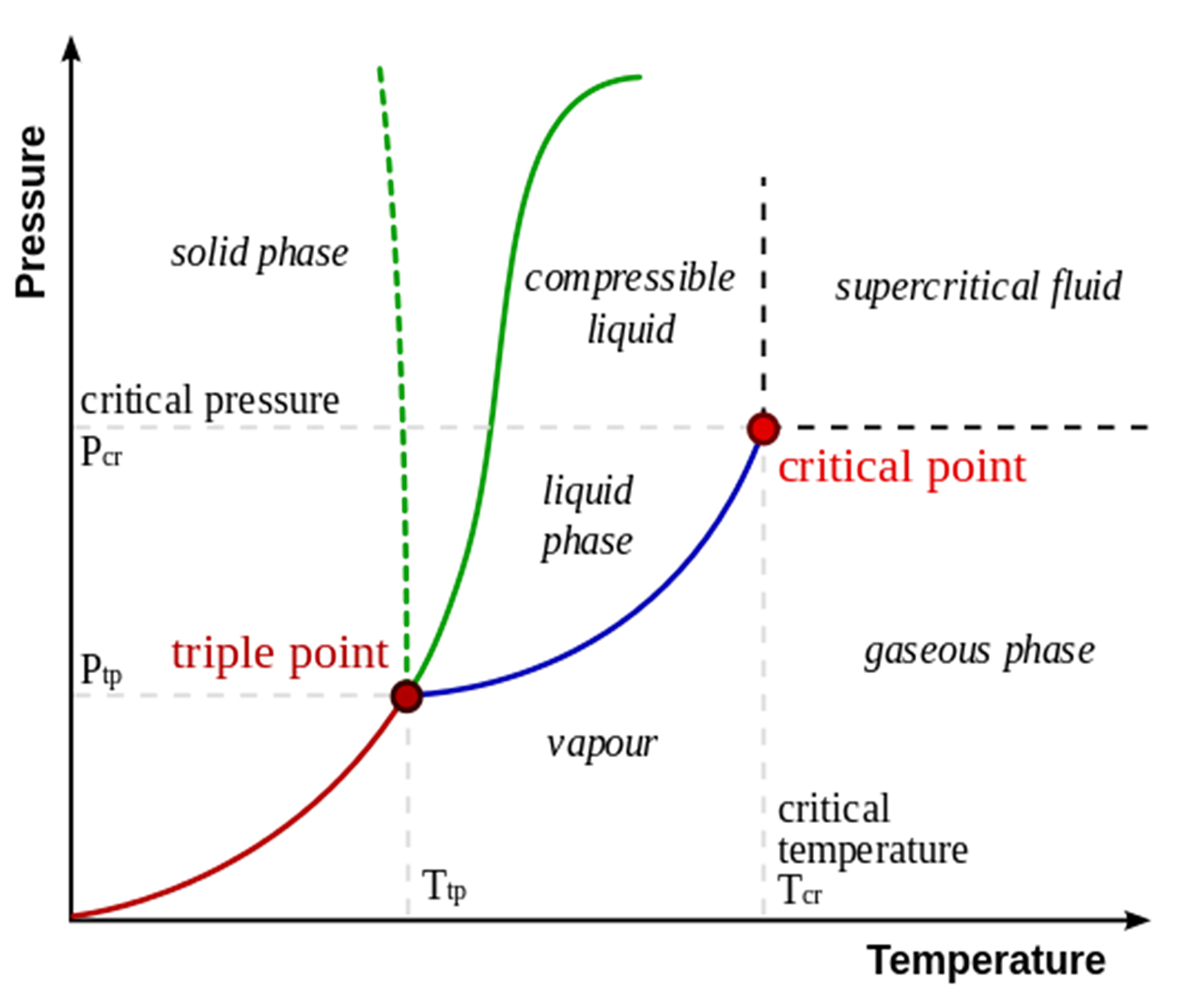

Vacuum freeze drying is a drying technology that uses the principle of sublimation to dehydrate materials. After the material is quickly frozen, it is heated in a vacuum environment (lower than the triple point pressure of water) to make the frozen water molecules directly sublimate into water vapor and escape. This process is called vacuum freeze drying.

2.Vacuum freeze drying process

Pretreatment

Depending on the source and application of the raw materials, the pretreatment methods are also different. For example, the pretreatment of fruits generally involves picking, washing and cutting, vegetables need to be blanched, and some products need to be steamed, etc.

Quick freezing

In order to solidify the moisture inside the raw materials, quick freezing is required. The shorter the freezing time, the faster the raw materials freeze, the smaller the internal crystals, and the less damage to the raw materials. Therefore, it is necessary to select a suitable freezing speed according to actual production.

Vacuum drying

Vacuum drying is usually divided into two stages: sublimation drying and analytical drying. Sublimation drying mainly targets free water in the material, while analytical drying mainly removes adsorbed water that is strongly bound to the solid. The vacuum degree, temperature and tray thickness during the drying process directly affect the drying process and product quality.

3.Advantages of vacuum freeze drying

Heat-sensitive products are not prone to denaturation or inactivation;

Some products have little loss of volatile components;

The product volume remains almost unchanged, maintaining the original structure and not condensing;

The dried product is loose and porous, sponge-like, and dissolves quickly and completely after adding water, recovering its original properties almost immediately;

Drying is carried out in a vacuum environment with very little oxygen, making the product less prone to oxidation;