Aquatic feed and aquarium feed production line adopts motor frequency conversion speed regulation technology, PLC control technology, automatic temperature control technology, etc., to maximize machine running stability and parameter accuracy to ensure stable machine output and feed quality. According to the age and foraging habits of different fish, shrimp and benthic animals, floating feed, slow sinking feed, sinking feed pellets, etc. are produced by adjusting machine parameters, raw material percentage, and changing molds, etc.

The feed produced by our machine has a high degree of maturation, high yield, uniform pellets size and balanced nutrition, which can meet the various production needs of the majority of fisheries owners, aquariums owners, fish pond owners and feed production plants. In addition, our fish feed machine can also produce extruded bait as well as dog food, cat food, bird food, and other pet food.

Jinan Kelid Machinery Co.,LTD. ’s twin-screw extruder is produced with famous motors, frequency converters, electrical components and high-quality stainless steel. Keep improving in equipment research and development, component processing, assembly process and automation control. If you can put forward specific ideas and requirements for machine material, degree of automation, machine output capacity, feed size, and raw material formula, we can provide feed production acknowledge and production line solutions accordingly.

Machine list:

Mixer— Screw conveyor— Double screw extruder— Air conveyor— Multi-layer belt dryer— Hoister— Flavoring roller— Oil(Slurry)sprayer— Cooling machine— Conveyor— Packing machine

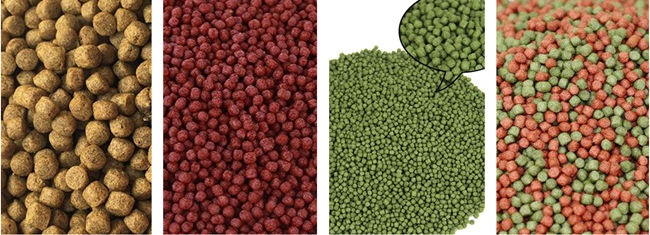

Sample:

|

Model |

KLD65 |

KLD70 |

KLD85 |

KLD95 steam |

|

Capacity (kg/h) |

140-160 |

240-260 |

500 |

800-1200 |

|

Installed Power (kw) |

71 |

103 |

175 |

190 |

|

Power Consumption (kw) |

43 |

60 |

105 |

135 |

|

Dimension (m) |

18.9*1.5*2.5 |

25.7*1.5*2.5 |

35.5*2.5*3.1 |

39*32*6 |

1. Help client to design the factory and offer professional advice and engineering drawing for the factory layout.

2. Report production progress regularly.

3. If the client can’t come to check the machine before delivery, Kelid helps the client check and make a testing report to show the details.

4. Provide user manual, factory inspection form, product certificate.

5. Provide 1-2 engineers to the client's factory for the installation and first-line workers' training.

6. After the installation, our engineer will assist you in on-site commissioning and personnel training (Training includes: equipment operation methods, precautions for use, equipment maintenance, etc.

7. Provide 13 months warranty and lifelong service.