In terms of transmission efficiency, among these three transmission methods, gear transmission is the most efficient, followed by sprocket chain transmission, and finally belt transmission. The biggest work loss is the belt drive. In the case of large obstructions, the pulleys and belts may often wear out.

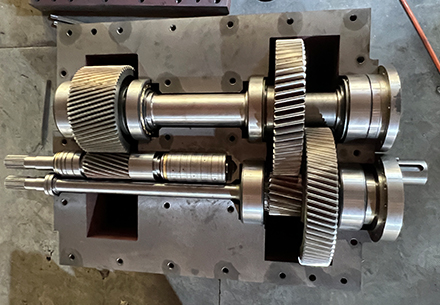

In terms of safety, most gear transmissions operate in a closed space, and generally have professional gearboxes, which are relatively safe; sprocket transmissions and belt transmissions are generally more exposed, and the probability of harm caused by contact with the human body is higher.

In terms of scope of application, direct connection and gear transmission are more used in large-scale projects or relatively high-end and sophisticated industrial projects; sprocket transmission and belt transmission are mainly used in small and medium-sized industrial machinery projects.

From the aspect of mechanical self-protection and loss prevention, belts are the best choice. When the equipment transmission parts are blocked, emergency stop or unexpected emergency stop is not possible, the belt transmission system will suffer the most damage. After the problem is solved, it only needs to be replaced. A new belt will suffice; however, the increased stability of the sprocket strip transmission also brings about the fact that if the sprocket cannot be stopped in an accident, there will be a great chance of causing damage to the machine itself and harm to the human body in the accident; Gear transmission in the event of an accident, the gear is the most easily damaged component.