Tel:+86-15715315973

Email: sales@kelidmachine.com

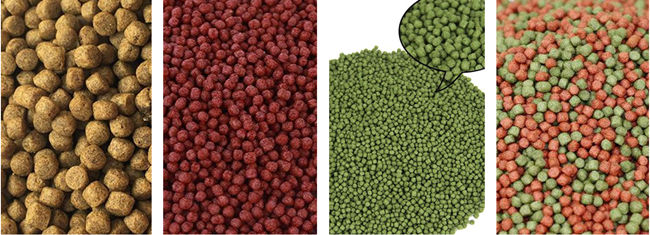

High-quality feed and pet food are essential for the growth of aquatic, aquarium, and pet animals. The twin-screw extruder is the must-have choice for all well-known feed and pet food producers. On the basis of the twin-screw extruder, in pursuit of higher quality food and machine capacity, we took the lead in producing a variety of animal foods for our customers by adopting the steam conditioning process, and accumulated valuable experience in this field. The feed and pet food produced by the wet extrusion process have high maturity, good palatability, uniform food pellet size, perfect color and balanced nutrition, and are the food health guarantee for various fish, dogs, cats, birds, etc.

The medium and large-scale aquatic feed, aquarium feed, and pet food production lines from Kelid company adopt steam conditioning technology, frequency conversion speed regulation technology, PLC control technology, automatic temperature control technology, etc., to maximize the machine running stability and parameter accuracy to ensure stable machine output capacity, high-quality product quality and prolong the lifetime of machine parts.

We can provide professional customized solutions according to the user's production requirements, raw materials, factory space, power capacity and investment budget, and so on. If you have any investment plans or ideas, please contact us!

Machine list:

Automatic raw materials batching grinding system— Steam conditioner— Double screw extruder— Cooling machine— Air conveyor— Multi-layer belt dryer— Hoister— Flavoring roller— Oil(Slurry)sprayer— Cooling machine— Storage bin— Packing machine

Sample:

|

Model |

Capacity (kg/h) |

Installed Power (kw) |

Dimension (m) |

|

KLD-70A |

400-600 |

34.7 |

3*0.9*2.5 |

|

KLD-70B |

800-1000 |

41.7 |

3.3*0.9*2.5 |

|

KLD-90A |

1000-1500 |

63.3 |

5.2*1.4*3 |

|

KLD-90B |

1500-2000 |

98.3 |

5.5*1.4*3 |

|

KLD-100A |

2000-3000 |

127.7 |

6.1*1.6*3.2 |

|

KLD-100B |

3000-4000 |

184.7 |

6.4*1.6*3.2 |

|

KLD-120 |

5000-6000 |

279.2 |

6.8*1.8*3.6 |

1. Help client to design the factory and offer professional advice and engineering drawing for the factory layout.

2. Report production progress regularly.

3. If the client can’t come to check the machine before delivery, Kelid helps the client check and make a testing report to show the details.

4. Provide user manual, factory inspection form, product certificate.

5. Provide 1-2 engineers to the client's factory for the installation and first-line workers' training.

6. After the installation, our engineer will assist you in on-site commissioning and personnel training (Training includes: equipment operation methods, precautions for use, equipment maintenance, etc.

7. Provide 13 months warranty and lifelong service.