In recent years, the need for modified starch has grown rapidly around the world. Jinan Kelid Machinery Co., Ltd has also been focusing on the research and development of modified starch production line.

The modified starch production line is an innovation of twin-screw extruder technology. This technology mainly uses corn starch, potato starch, tapioca starch, wheat starch, etc. as the main raw materials. Under the action of high temperature and pressure of the twin-screw extruder, the starch original molecule size, physical and chemical properties have been changed, thereby changing the natural characteristics of starch, such as gelatinization temperature, thermal viscosity, stability, gel strength, transparency, etc., make it more suitable for certain application requirements. As one of the important auxiliary materials in the industry, modified starch is widely used in papermaking, food, textile, construction, medicine and other industries.

The modified starch production line developed by Jinan Kelid Machinery Co., Ltd has the characteristics of high capacity, energy-saving, high efficiency, convenient operation, no pollution, ECO-friendly, and so on. Normally, the modified starch production line adopts DELTA inverter, CHINT electric device, and LEADGO motor. But SIEMENS, ABB, and other international famous brands electrical parts are usually be used as well.

Machine list:

Mixer— Screw Conveyor— Twin-Screw Extruder— Air Conveyor— Multi-Layer Mesh Belt Dryer— Hoister— Pulverizer— Packaging Machine

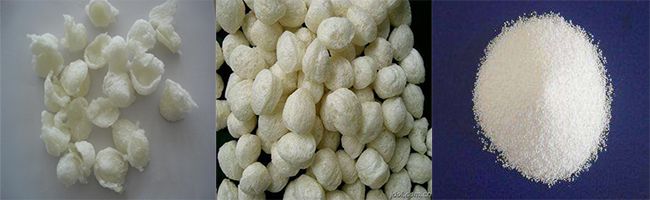

Sample:

|

Model |

KLD65 |

KLD70 |

KLD85 |

KLD95 |

|

Capacity (kg/h) |

140-160 |

240-260 |

400-500 |

800-1000 |

|

Installed Power |

79 |

110 |

200 |

270 |

|

Power Consumption (kw) |

55 |

65 |

120 |

160 |

|

Dimension (m) |

15.9x2.5x2 |

16.4x2.5x2.5 |

26.4x2.5x3 |

33.5X2.5X3.0 |

1. Help client to design the factory and offer professional advice and engineering drawing for the factory layout.

2. Report production progress regularly.

3. If the client can’t come to check the machine before delivery, Kelid helps the client check and make a testing report to show the details.

4. Provide user manual, factory inspection form, product certificate.

5. Provide 1-2 engineers to the client's factory for the installation and first-line workers' training.

6. After the installation, our engineer will assist you in on-site commissioning and personnel training (Training includes: equipment operation methods, precautions for use, equipment maintenance, etc.

7. Provide 13 months warranty and lifelong service.