The nutrition powder production line produced by Jinan Kelid Machinery Co., Ltd adopts rice flour, corn flour, oat flour, wheat flour, and other whole grains flour as main raw materials. With vegetables, fruits, eggs, meat, calcium, phosphorus, iron, vitamins, and other optional ingredients. Then through the extrusion puffing process to cure the raw materials, to get the nutrition powder products that are convenient to eat, fragrant in taste, and rich in nutrients. The starch is denatured by the action of high temperature and pressure of the extruder, the protein is organized, the crude fiber is refined, the pathogenic bacteria are killed, and the nutrition is more easily absorbed by the human body.

The nutrition powder production line is highly automated. The processes of mixing, extrusion puffing, drying, crushing, weighing and packaging are completed automatically. Compared with the traditional production method, it can process a wider range of raw materials, high production efficiency, stable product quality, and simple operation.

Nutrition powder is widely used in various baby rice flour, whole grain flour, oat flour, sesame paste, walnut paste, and other products.

Jinan Kelid Machinery Co., Ltd. can also provide production line layout diagrams according to customer workshop conditions.

Machine list:

Mixer— Screw Conveyor— Twin-Screw Extruder— Air Conveyor— Multi-Layer Mesh Belt Dryer— Hoister— Pulverizer— Packaging Machine

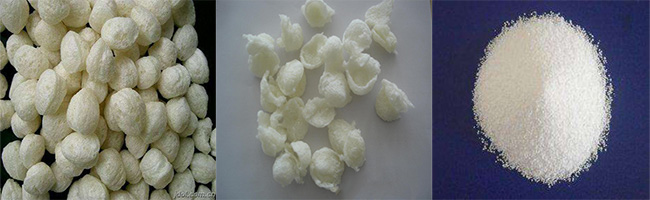

Samples:

|

Model |

KLD65 |

KLD70 |

KLD85 |

KLD95 |

|

Capacity (kg/h) |

140-160 |

240-260 |

400-500 |

800-1000 |

|

Installed Power |

79 |

110 |

200 |

270 |

|

Power Consumption (kw) |

55 |

65 |

120 |

160 |

|

Dimension (m) |

15.9x2.5x2 |

16.4x2.5x2.5 |

26.4x2.5x3 |

33.5X2.5X3.0 |

1. Help client to design the factory and offer professional advice and engineering drawing for the factory layout.

2. Report production progress regularly.

3. If the client can’t come to check the machine before delivery, Kelid helps the client check and make a testing report to show the details.

4. Provide user manual, factory inspection form, product certificate.

5. Provide 1-2 engineers to the client's factory for the installation and first-line workers' training.

6. After the installation, our engineer will assist you in on-site commissioning and personnel training (Training includes: equipment operation methods, precautions for use, equipment maintenance, etc.

7. Provide 13 months warranty and lifelong service.