With the growing pet population, the demand for pet food is increasing day by day. In addition to canine puffed dry food, the market demand for chewing snack products should not be underestimated. The important functions of dog chews include: cleaning teeth, reducing calculus, cleaning the mouth, and feeling happy. Products based on training can also increase the exercise amount of dogs, thereby enhancing their physique.

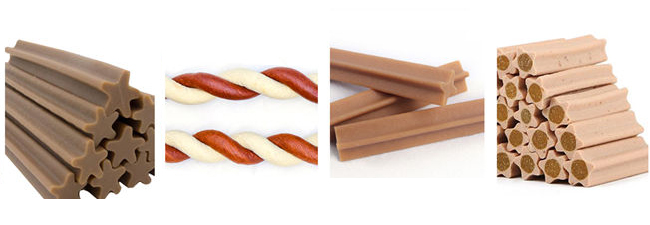

In addition to the pet dry food production line, our company is deeply engaged in the research and development of pet chewing equipment, and provides professional and reasonable solutions for the production of single-color chews, two-color chews, sandwich chews and injection molding chews. Specific product shapes include column, bone, strip, spiral, granule, heart, fruit, etc. We can design machines and related molds according to the shape requirements of customers, so that the majority of dog lovers and dogs like chewing snacks products.

The pet chew production line’s features of flexible allocation, novel mold design, excellent machine material, high automation degree, easy operation, etc. which is favored by domestic and foreign pet product manufacturers. Let us work with dog lovers to build a healthy fortress for dogs. If you have the same desire or investment goal, welcome to contact us.

Machine list:

Ingredients mixer— Screw conveyor— Single screw extruder(with water recycle cooling system)— Cooling conveying machine— Cutting machine— Hoister— Dryer— Packing machine

Sample:

|

Model |

KLD100-I |

KLD100-II |

|

Capacity(kg/h) |

80-120 |

160-240 |

|

Installed power (kw) |

92 |

170 |

|

Consumption (kw) |

55 |

100 |

|

Equipment size (m) |

21.4x1.3x2.5 |

22.1x8.5x1.8 |

1. Help client to design the factory and offer professional advice and engineering drawing for the factory layout.

2. Report production progress regularly.

3. If the client can’t come to check the machine before delivery, Kelid helps the client check and make a testing report to show the details.

4. Provide user manual, factory inspection form, product certificate.

5. Provide 1-2 engineers to the client's factory for the installation and first-line workers' training.

6. After the installation, our engineer will assist you in on-site commissioning and personnel training (Training includes: equipment operation methods, precautions for use, equipment maintenance, etc.

7. Provide 13 months warranty and lifelong service.