With different craft requirements, there are continuous drum popcorn machine and intermittent popcorn machine that can be chosen. The material of the machines is food-grade stainless steel. With different energy requirements, we can provide the electric heating popcorn machine, gas heating popcorn.

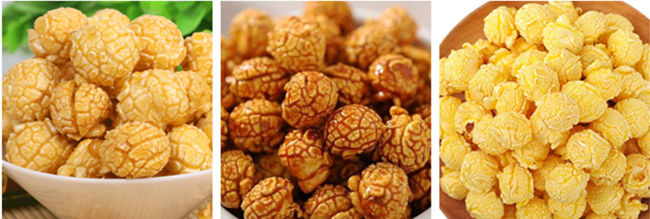

The intermittent automatic popcorn machine adopts automatic mixing to make the popcorn uniform in color and crisp in taste. Flavoring is carried out at the same time as puffing, and spherical popcorn with different flavors can be produced according to customer requirements. The pot body is automatically turned over and discharged, so that the popcorn can be separated from the pot as soon as possible to prevent the pot waste heat from causing the popcorn to scorch. This popcorn machine coats sugar evenly, the formula is easy to adjust, and it can produce popcorn with different flavors, such as original, caramel, strawberry, coconut, dark chocolate, etc.

For continuous popcorn machines, it's match up with fully automatic production line for puffing and wrapping sugar, with a high degree of automation, simple operation and stable quality.

Sample:

Continuous drum popcorn machine

|

Dimension |

2500*1600*2900mm |

Volume of outlet silo |

60L |

|

Burner model |

Baltur BTG11 |

Capacity |

70KG/H |

|

Fan motor |

5.5KW |

Main motor |

0.75KW |

Intermittent popcorn machine

| Diameter of pot |

700mm |

Depth of pot |

350mm |

|

Material of pot |

Stainless steel |

Way out of the pot |

the pot turnover the materials out to the discharge port automatically. |

|

Main shaft revolution speed |

6.7-33shift/min |

Stir the rotation speed |

14-69.3shift/min |

1. Help client to design the factory and offer professional advice and engineering drawing for the factory layout.

2. Report production progress regularly.

3. If the client can’t come to check the machine before delivery, Kelid helps the client check and make a testing report to show the details.

4. Provide user manual, factory inspection form, product certificate.

5. Provide 1-2 engineers to the client's factory for the installation and first-line workers' training.

6. After the installation, our engineer will assist you in on-site commissioning and personnel training (Training includes: equipment operation methods, precautions for use, equipment maintenance, etc.

7. Provide 13 months warranty and lifelong service.