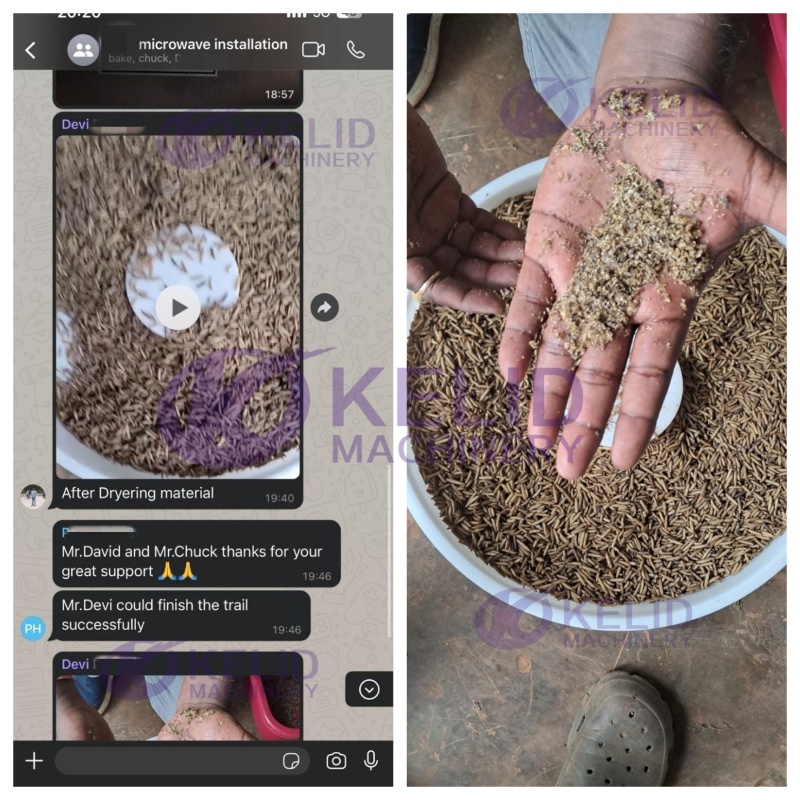

Mr. Devi, as an employee of a black soldier fly breeding and processing company, recently purchased a cabinet microwave dryer from our company. After half a month of actual use, the effect far exceeded expectations! Hereby share the real experience:

1. High drying efficiency

Compared with traditional hot air drying, the microwave drying speed is increased by about 60%. It only takes 19 minutes to process 20 kg of fresh insects at a time, and no preheating is required, which significantly reduces the time cost.

2. Stable and uniform quality

Microwave penetrating heating completely solves the problem of uneven inside and outside of traditional drying. The moisture content of the finished product is stably controlled at about 5%, the insect body integrity rate is as high as 98%, the color is golden and not burnt, and the protein nutrition is zero loss.

3. Outstanding advantages in energy saving and environmental protection

The comprehensive energy consumption of the equipment is 35% lower than that of electric heating drying, and there is no exhaust gas emission, which meets the requirements of environmental protection production.

4. Convenient operation and easy maintenance

The key operation is very simple, and new employees can get started in 30 minutes. Easy to clean, no insect debris remains, and the average daily maintenance time is saved by 1.5 hours.

5. Professional and timely after-sales service

The technical team provides process parameter debugging services, and the remote guidance responds quickly. The equipment is installed and debugged the next day after arrival to ensure seamless production.

If you are also engaged in black soldier fly larvae breeding or processing, try using kelid machinery's microwave dryer. The effect will not disappoint you!