At present, the pet food production line of Jinan Kelid Machinery Co., Ltd. mainly includes the following processes and configurations:

1. Twin screw extrusion process:

Raw material: The main raw materials are meat meal, bone meal, grain powder, etc., and the effect of ripening and forming is achieved through extrusion and puffing.

Energy: The equipment mainly uses electricity. According to different requirements of customers, drying part energy can be gas, fuel oil, and steam.

Process flow: crushing--mixing--extrusion--drying --spraying--cooling--packaging

Product features: The produced granules are puffed granules, which are hard and brittle, easy to digest, and easy to store. Usually packed in plastic bags, nylon bags, or paper bags.

Formula: We will provide raw material formulas for customers to calculate their own cost expenditures as accurately as possible according to the actual situation of their local raw material procurement, and can achieve cost optimization on the basis of ensuring excellent food nutrition ratio.

Product picture:

2.Single screw extrusion process

Raw materials: The main raw materials are powdered raw materials with relatively high content of animal protein and fat such as oil and meat, which are cured by heating and extruded into shapes, but the temperature range needs to be precisely controlled to prevent puffing.

Energy: The equipment mainly uses electricity, and drying part energy can be gas, fuel oil, steam.

Process flow: crushing and mixing--extrusion--cooling (preliminary drainage to solidify the surface)--baking at low temperature for uniform moisture--spraying powder on the surface to season-- Low-temperature drying--cooling--packaging

Product features: Compared with puffed granules, because of the high content of meat and oil, this product is soft and sticky, and has a relatively short shelf life. It is mainly concentrated in the high-end pet food market, and there are many small-space sealed packaging and iron box packaging.

Formula: We provide basic formula, and customers can adjust and change the ratio of raw materials according to their actual market demand and taste requirements.

Product pictures:

3.Cold pressing process

Raw materials: The main raw material is powdered/ Pasted meat bone, with less starch content, and the molding effect is achieved by cold pressing with a mold.

Energy: The equipment mainly uses electricity, and drying part energy can be gas, fuel oil, steam.

Process flow: crushing and mixing of meat and bone raw materials--cold pressing--drying--cooling--packaging

Product features: The product mainly focuses on the high-end pet food market.

Formula: We have basic formula. Customers can independently adjust the types and proportions of raw materials according to their actual raw material procurement conditions, on the premise of reasonable nutritional mix and guaranteed molding effect, so as to increase product types and profit margins.

Product pictures:

4.Hot air drying process:

Raw materials: Pure meat is used as the main raw material.

Energy: The equipment mainly uses electricity.

Process flow: cut the meat into granules--drying--cooling--packaging

Product features: Fresh meat is dried by hot air. Keeping the texture of the meat can ensure the basic taste, the process is simple, and the operation is convenient.

Formula: no special formula is required.

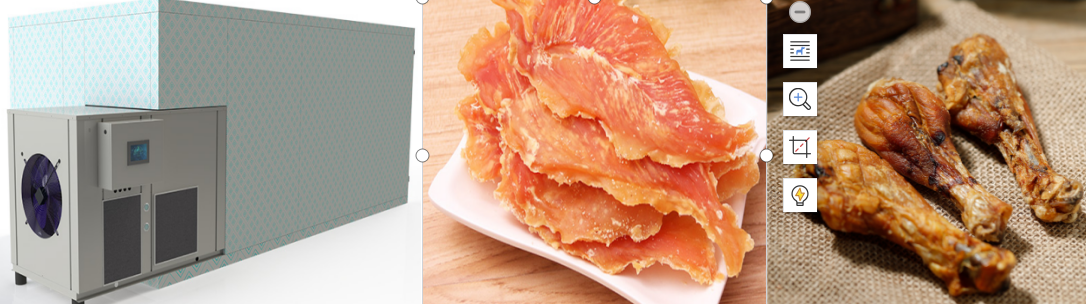

Product pictures:

5.Vacuum freeze-drying process:

Raw materials: Pure meat is used as the main raw material. After the meat is cut into cubes, the water is drained by sublimation and freeze-drying in an advanced vacuum environment to achieve the effect of drying pure meat particles.

Energy: The equipment mainly uses electricity.

Process flow: Meat diced into granules--pretreatment--vacuum freeze-drying--cooling--packaging.

Product features: Fresh meat is heated and dried in a vacuum environment, and the water is sublimated extremely quickly. The structure and taste of meat are preserved to the greatest extent, the process is simple but the processing accuracy is very high, the equipment is easy to operate but the structure is complex, and the function configuration is complete. Freeze-dried meat granules have good rehydration properties, and the taste remains the same after rehydration, which has been widely praised.

Formula: All kinds of frozen meat raw granules, no special special formula is required.